22 mins read

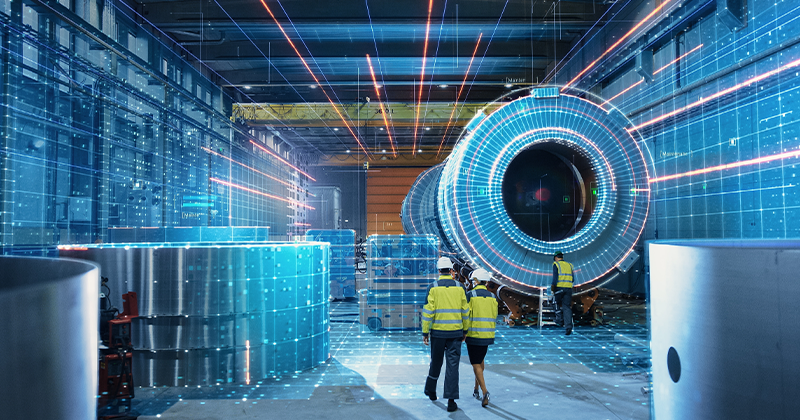

Construction: The Power Digital Twin Technology

When used optimally, Digital Twin technology is a powerful tool in the hands of construction industry players and project owners.

As a virtual digital replica of a real object, such as a building or city, a Digital Twin’s primary role is to inform construction teams’ decision-making during the design, engineering, building and operating, and maintenance phases of complex builds.

RIB CCS Head of Sales and Customer Success, Fady Kobersy, says engineers in the AEC industry are most challenged by the practical application of new building designs and projects. “This means that construction designers are limited in their creativity because if a creative building design is developed, it must be approved to comply with all safety regulations. It would take a great deal of capital, time, and other resources to test the brand-new design in the real world.

“Building developers could cut the timeframe in which they could share their ideas and get them approved ten times faster if they could test out their ideas in reality-based simulations that included all the necessary real-world factors (such as gravity, weather, wind, etc.).

“Because the simulation directly derives data from the world, new building designs would be tested for safety, practicality and sustainability in a simulation, and the feedback would be as accurate as if the test were conducted in real life,” adds Kobersy.

A Digital Twin therefore connects real-world models to their digital versions, allowing for better visualisation of particular assets. “A Digital Twin can be highly complex or fairly simple. The amount of data that is collected will determine just how much the virtual model is able to imitate the real-world project,” says Kobersy.

Notably, there are three main types of Digital Twin:

- Digital Twin Prototype (DTP): a prototype of a physical asset, including the design, analyses and processes of the physical project.

- Digital Twin Instance (DTI): an individual digital twin for each component of a product (or building) once it is manufactured or executed.

- Digital Twin Aggregate (DTA): the combination or aggregation of all the DTIs, incorporating all of the relevant data and information.

Kobersy says key to Digital Twin technology is its ability to receive feedback from a real-life model, which allows the 3D computerised version to analyse, understand and mimic the current situation.

“The Digital Twin and data can either be used with a conceptual protype for analysis purposes during project execution, or in the form of a virtual execution and simulation of the project before it begins.”

The adoption of Digital Twin technology and concepts allows for collaboration between multiple departments – from designers, engineers and planners, to the people who are executing the project – and allows for better informed decision-making at every stage.

Importantly, a digital twin should not be confused with Building Information Modelling (BIM) technology. While there are similarities, BIM focuses on the design and construction of a building, whereas a Digital Twin is a simulation of how humans interact with their surroundings i.e., connecting physical and virtual worlds.

Kobersy says the multidisciplinary collaboration and communication process of creating Digital Twins leads to cost reductions during the execution stage, because potential site problems (and safety and quality issues) can be eliminated ahead of time. “In addition, owners can optimise the operation and maintenance of their projects post-handover, with digital twin analyses serving as preventive plans.

“Ultimately, having access to relevant data in real time boosts the design, execution, handover and management of projects. Digital Twins, which sometimes include VR and AR technology, elevate how we operate and optimise best case scenarios; transform new construction projects to allow for creative modern design; optimise the utilisation of space; reduce construction problems and automate facility management,” he concludes.

Most Recent

22 mins read

22 mins read

15 mins read

49 mins read

E-BOOK